What is Electropolishing?

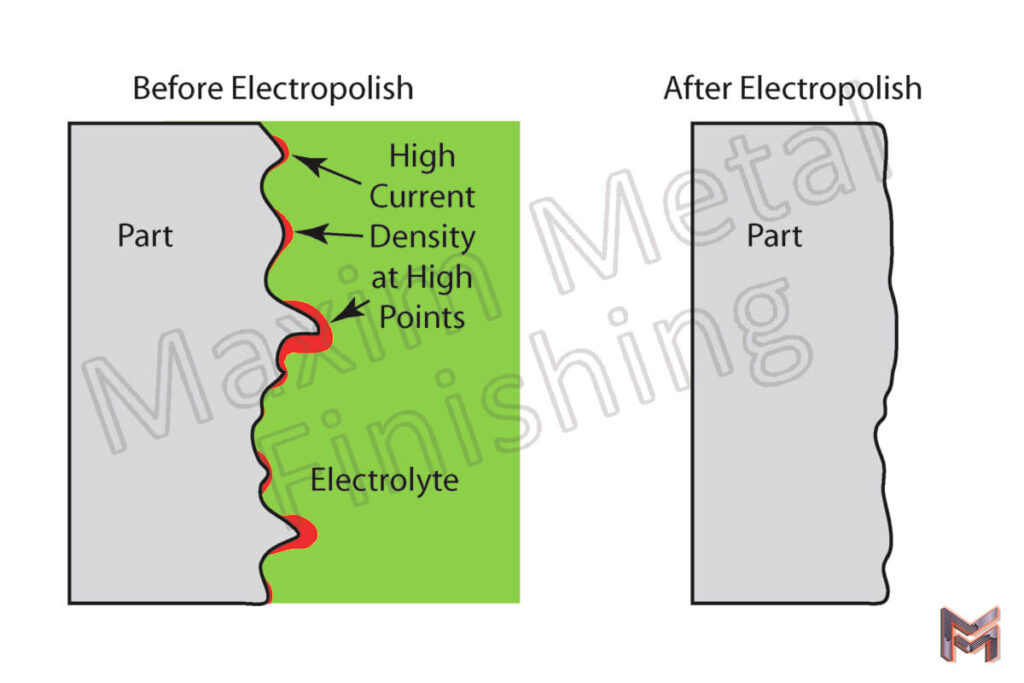

Electropolishing is an electrochemical finishing procedure that removes a small material coating of a metal item, usually stainless steel or comparable alloys. The procedure produces a gleaming, smooth, and ultra-clean surface. Electropolishing, also known as electrochemical polishing, anodic polishing, or electrolytic polishing, is particularly useful for polishing and deburring delicate or complicated geometries.

It is easy to mistake the procedure with passivation; however, electropolishing is not the same as passivation. Both are chemical processes that are not mechanical, but only electropolishing uses electricity. Both passivation and electropolishing are processes intended to improve corrosion resistance.

Benefits of Electropolishing

There are several well-known benefits to our Electropolishing services. A few of these benefits are mentioned below,

- Improved Corrosion Resistance is one of the main outcomes of Electropolishing. All forms of corrosion begin on or near a metal’s surface, and electropolishing removes surface material and surface contaminants. It dissolves free iron, inclusions, and embedded particles from a material’s surface.

- Enhances Surface – Electropolishing improves the appearance of a material’s surface while also improving seals, lowering friction, reducing real surface area, allowing easier sanitation, and improving light and heat reflection.

- Reduces Adhesion and improves ease of cleaning – The improved micro finish achieved through electropolishing reduces a material’s adhesion and contamination buildup.

- Deburring – Electropolishing removes sharp edges or burrs from a material – ensuring that the material has smooth edges and surface.

- Appearance – One of the main benefits of electropolishing is the result of a lustrous surface appearance. The non-chemical process does not use tools for the polishing process; hence there are zero risks of direction polishing lines.

Who uses Electropolishing?

Electropolishing is a well-known finishing process that many scientists and industries have commercially used since the 1950s. This common finishing procedure is used across a wide variety of industries such as,

– Food, beverage, and pharmaceutical processors

– Aerospace manufacturers

– Semiconductor manufacturers

– Automakers and the racing industry

– Surgeons and dentists

Types of Electropolishing services offered by us

Below is a list of the electropolishing services that we offer. We ensure that our services are delivered with the best possible quality and care. Our services are as follows,

Stainless Steel Electropolishing

Electropolishing stainless steel is a “reverse plating” process that uses an electrochemical solution to remove the outer skin of a metal part. By stripping away a uniform layer of surface material, our process also removes embedded contaminants, heat tint and oxide scale, burrs, micro cracks, pits, and other surface imperfections that can compromise the performance and longevity of a part.

Aluminum Steel Electropolishing

Our electropolishing process will greatly reduce the microroughness of aluminum surfaces, resulting in a high gloss even at low mass losses. Electropolishing aluminum is a metal-removing anodic process in an electrolyte based on phosphoric acid and sulfuric acid.

Copper Steel Electropolishing

Our electropolishing services can apply to copper alloys as well. This process ensures the removal of tarnishing and roughness on copper’s surface, imparting a smooth and bright surface under suitable conditions.

Titanium Steel Electropolishing

Our electropolishing process ensures that the titanium parts last and perform better. Titanium’s natural resistance to corrosion, high temperatures, high tensile strength, and biocompatibility make it a viable and renowned alloy in aerospace, medical and marine applications. This is why we make sure to improve performance through electropolishing while maintaining the properties that make this alloy unique.

Nickel Alloy Electropolishing

Our electropolishing services also include Nickel Alloys. Our process ensures nickel parts are left with a bright and smooth finish that’s free from any form of imperfections on the material’s surface and edges. As with any of our other electropolishing services, we also ensure enhanced corrosion resistance and increased longevity.

Hastelloy Alloy Electropolishing

Many organizations frequently use Hastelloy as critical components of nuclear and chemical equipment. This demands very careful manufacturing to eliminate any form of surface imperfections. Our electropolishing service is guaranteed to remove a controlled, uniform layer of surface material from any Hastelloy part that ensures a smooth and bright surface with no imperfections.